Friction Stir Welding vs. Traditional Welding - Mazak MegaStir

Invented in 1991 by Wayne Thomas at TWI (The Welding Institute), Friction Stir Welding was initially regarded as an experimental process with few practical applications, if any. Over time, however, it soon became clear that FSW, which plasticizes material rather than melting it, not only rivaled but greatly improved upon traditional fusion welding techniques. The result is a technology that revolutionizes fabrication and offers a more efficient way to perform a wide range of industrial welding applications.

Friction Stir Welding vs. Traditional Welding

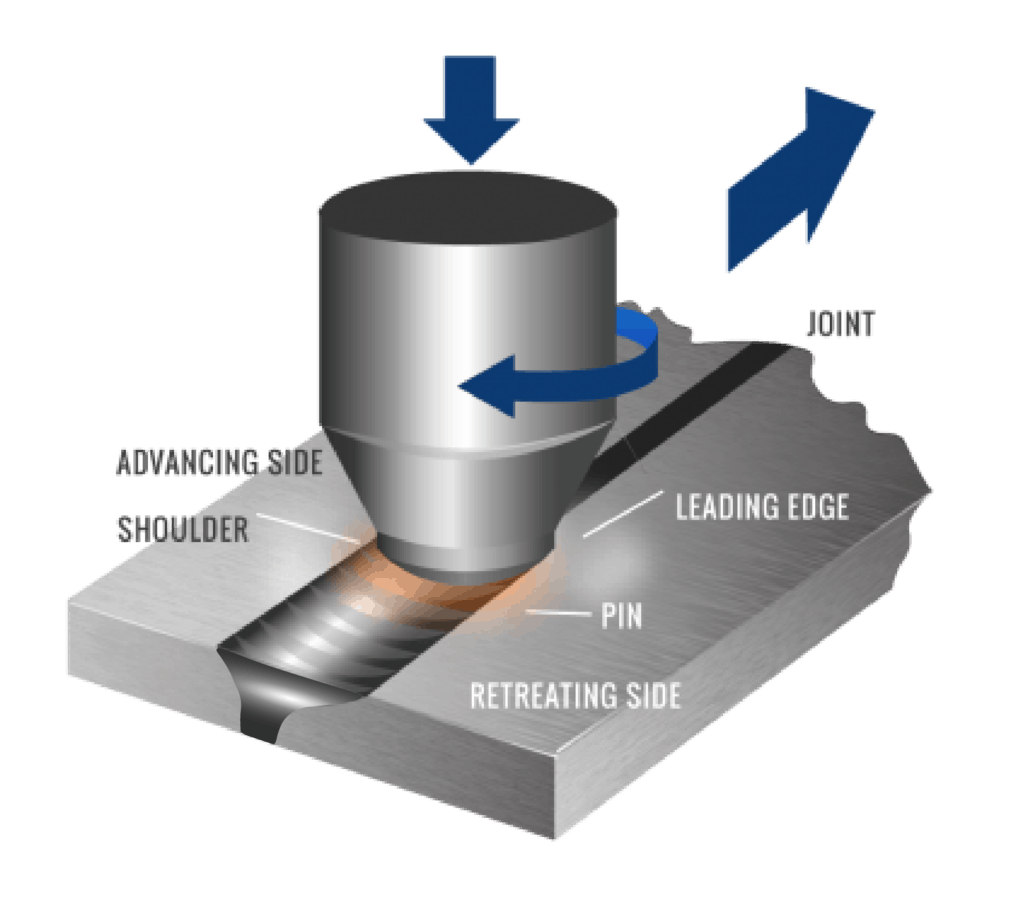

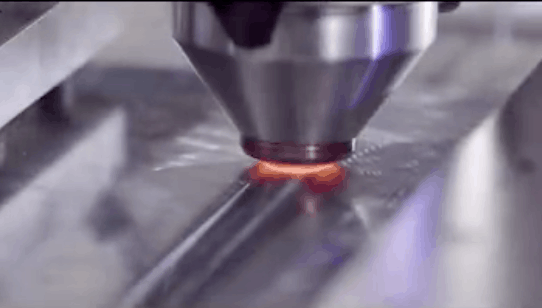

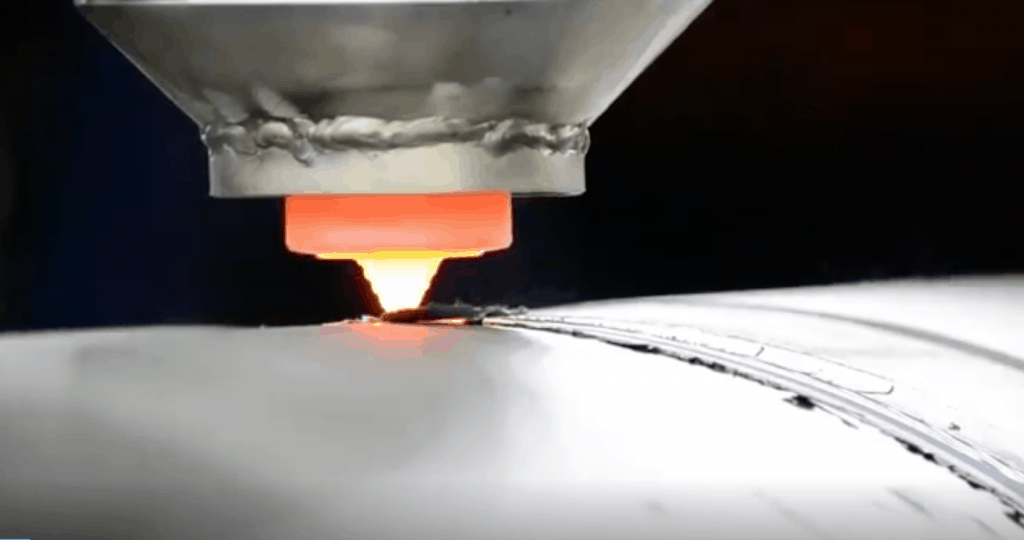

In Friction Stir Welding, a cylindrical shouldered tool with a profiled pin is rotated and plunged into the joint area between two pieces of sheet or plate material. The frictional heat between the wear-resistant welding tool and the workpieces causes the latter to soften without reaching the materials’ melting point, allowing the tool to traverse along the weld line without shielding gas or filler wire. The plasticized material, transferred to the trailing edge of the tool pin, is forged through contact with the tool shoulder and pin profile. On cooling, a solid phase bond is created between the workpieces.

Friction Stir Welding

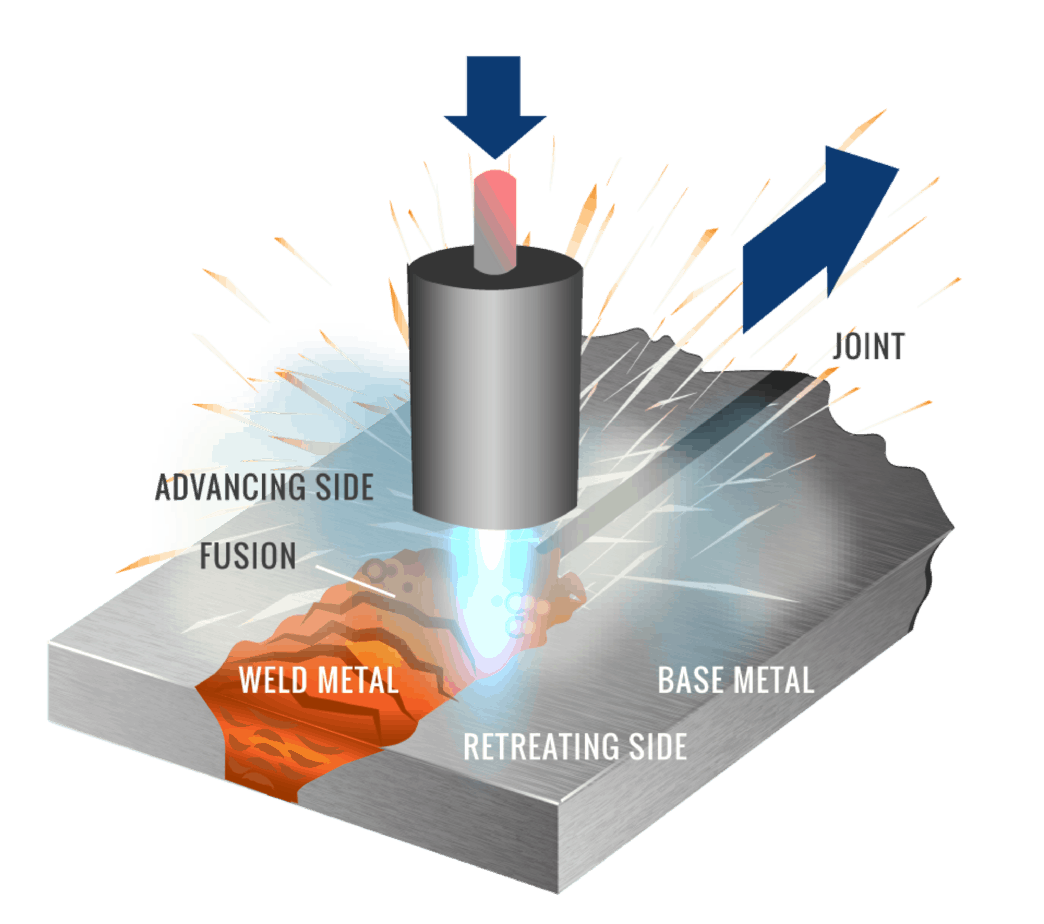

Traditional Fusion Welding

Benefits of Friction Stir Welding

Weldable Alloys

- High-strength

- Pipeline (x65, x80, x100)

- Stainless (austenitic, duplex)

- Automotive (AHSS)

- Invar

- Nickel, zinc, silicon and tin-alloyed materials

- 200

- 600

- 625

- 718

- 1,000

- 2,000

- 3,000

- 5,000

- 6,000

- 7,000

- Metal matrix composites

- Commercially pure

- Alpha-beta phase

Unique Characteristics

With arc welding, calculating heat input is critically important when preparing welding procedure specifications (WPS) for the production process. With FSW, the traditional components – current and voltage – are not present, as the heat input is purely mechanical and thereby replaced by force, friction and rotation. As a result, the FSW process forms joints at about 80-90% of the base material’s melting temperature, creating a joint that is nearly always superior to conventional fusion-welded joints.

Ideal Parameters

When using FSW, the following parameters are controlled: downforce, welding speed, the rotational speed of the welding tool and tilting angle. Only these four main parameters need to be mastered, making FSW ideal for mechanized welding. And of these four, the most important variable is downforce, which enables robust control even at higher welding speeds. Greater downforce produces the generation of frictional heat, thus softening the material further and helping to guarantee high quality even where tolerance errors in the materials to be joined may arise.

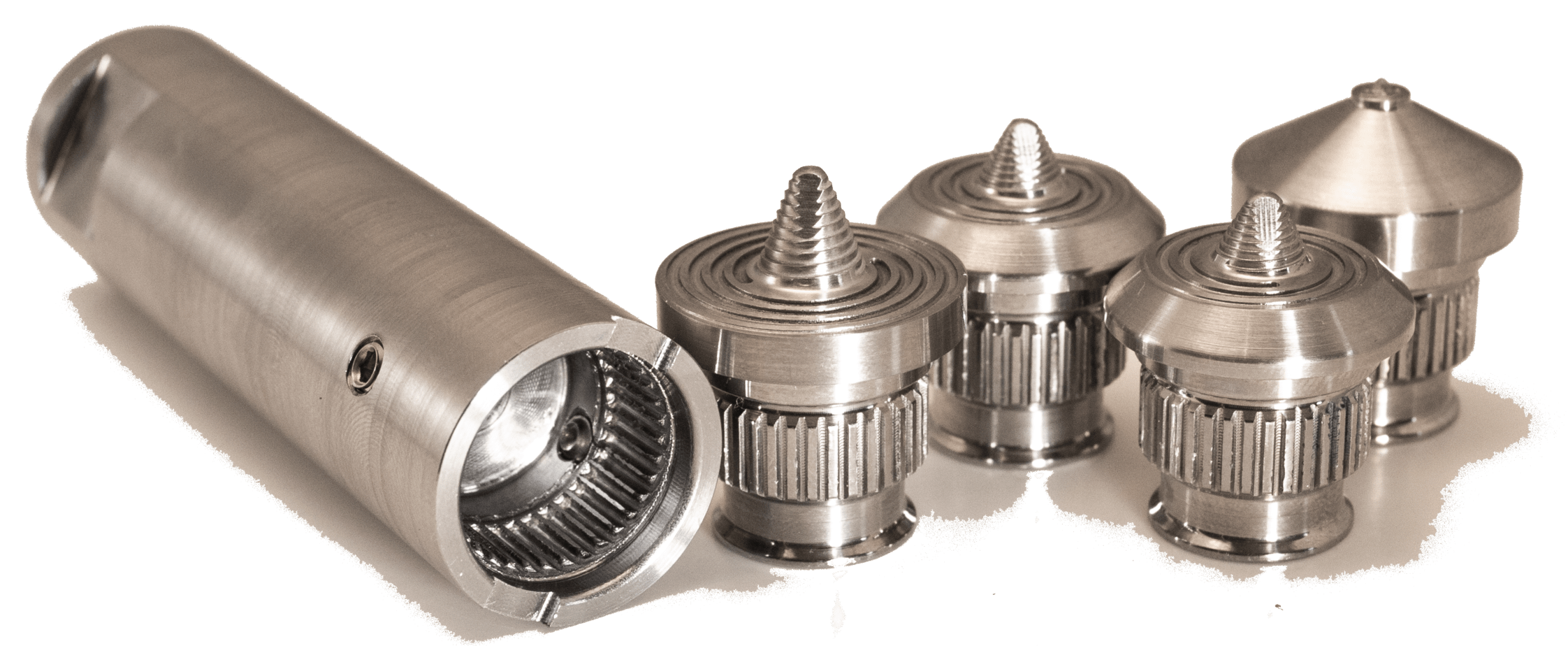

The Right Tools & Design

Optimizing tool geometry to produce more heat or achieve efficient stirring offers two main benefits: improved breaking and mixing of workpieces’ oxide layers and more efficient heat generation, yielding higher welding speeds and enhanced quality. And Mazak MegaStir is the only FSW service provider to design and build advanced instrumented tool holders and tools that support both ferrous and non-ferrous alloys.

Unrivaled Performance for Significant Cost Savings and Increased Production Capacity

Download the Mazak Megastir Brochure

WHAT SOLUTION IS RIGHT FOR YOUR PROJECT?

Achieve a better weld today with full-function Friction Stir Welding technology from Mazak MegaStir.