VIDEOS - Mazak MegaStir

Mazak MegaStir is working with Bechtel and BYU to make Additive Friction Stir Deposition (AFSD) a commercially available Manufacturing Technology.

Discover how a Mazak customer leverages patented Hybrid FSW technology, combined with Mazak MegaStir’s diamond pin tooling, to produce a hermetic electronics chassis for the aerospace industry.

Discover how a Mazak customer use our patented ultrahard Friction Stir Welding (FSW) pin tools to join an 8mm steel flange to a steel pipe fitting in a single pass.

Russell Steel discusses how to increase productivity in Friction Stir Welding is by taking advantage of diamond friction stir welding tools produced by Mazak MegaStir.

Dale Fleck gives a walk through of the Mazak MegaStir factory, established in 2002.

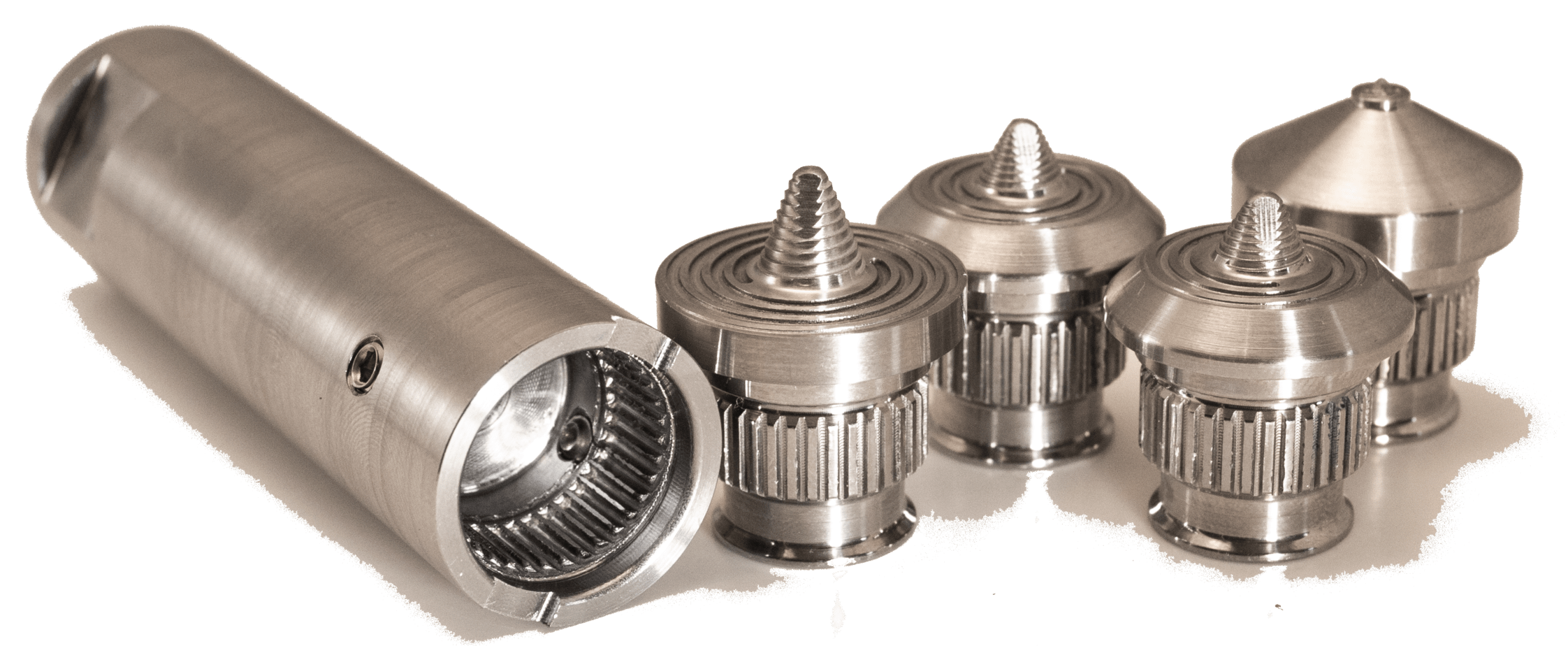

AA6061 Friction Stir Welded with adjustable pin tool for material up to 1 3/8 thick.

Friction stir welding two copper coupons to demonstrate single pass 25mm thick welding from single side.

Friction stir welding two halves using an internal mounted anvil. Parts were completed to create specific gravity frac balls.

Friction stir welding stainless steel to steel. This bimetallic welding process allows lap joint to join materials with minimal heat affect to both alloys reducing distortion and need for post weld heat treat.

Friction Stir Welding coupons to demonstrate low distortion/heat during the process.

Friction stir welding two plates together using PCBN pin tool to minimize tool wear due to boron carbide particles.

Friction Stir Welding demonstration on linear pipe seam.

Friction stir welding high temperature Haynes 224.

Friction stir welding API grade steel using PCBN pin tooling.

Friction Stir Welding steel using PCBN on API grade steel on pipe.

Friction Stir Welding using PCBN on 0.125" thick steel. Major value in FSW joint is refined grain structure that replicates base metal properties, higher strength than conventional welding processes with flat weld profile.

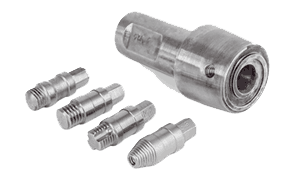

FSW on 6061-T6 3mm thick aluminum. Mazak VTC-800 utilizing MegaStir toolholder with bluetooth force feedback. System provides customers with closed loop force control and the ability to monitor temperature of the tool. Machine center can swap out FSW toolholder with cutting tools to either pre or post weld machine part.

FSW lap weld Aluminum 2219 to Aluminum boron carbide composite (Metamic – produced by Holtec). 200 rpm at 12ipm with 12,000# force.

Friction Stir Welding 20mm Copper DHP using MegaStir designed pin tool (Densimet). 250 RPM traveling at 6 ipm.

Friction Stir Welding 19mm (.75") X65 Steel using PCBN pin tool. Single pass welds traveling 100mm/m (4 ipm).

Friction Stir Processing D2 Steel with PCBN pin tool to increase hardness properties in order to extend valve seat life.

Download the Mazak Megastir Brochure

WHAT SOLUTION IS RIGHT FOR YOUR PROJECT?

Achieve a better weld today with full-function Friction Stir Welding technology from Mazak MegaStir.